Whether you’re an experienced marketer or an early career professional, you've probably perused countless catalogs, magazines, and other promotional materials without ever focusing on the specific details that attracted you to them in the first place. That is, until it’s time to print one yourself. Regardless of your background or tenure, if you're spearheading a direct mail initiative for your company, it must look and feel spectacular and be effective.

It's therefore critical to select the optimal printing process from the outset.

Design Distributors recognizes that even the most experienced marketers likely can't describe the difference between sheet-fed printing and offset web press printing.

Why should they? The only thing that matters is the end product and how it will ultimately influence the perception of your brand.

In this explainer, we highlight the major differences between sheet-fed and web press printing and outline how both options can positively influence the success of your direct mail marketing campaign.

From a marketing standpoint, here is what you need to know about the two printing techniques:

Similarities Between Sheet-Fed & Web Press Printing

Sheet-fed and web press printing are both viable solutions for creating promotional materials industrially.

These methods are ideal for orders of 1,000 or more pieces of everything from tri-fold brochures to order cards to lithographed envelopes and even bi-colored letterheads—you name it, we print it.

Differences Between Sheet-Fed & Web Press Printing

The Mechanics Behind Each

Sheet-fed, as its name indicates, involves single, individual pages quite literally fed into a press. On the other hand, web press printing utilizes one continuous roll of paper.

Speed & Volume

While sheet-fed presses are the go-to solution for projects more concerned with enhanced quality, web presses tend to be more expeditious at handling larger quantities for bigger jobs.

The chief distinctions between the two techniques are evident in the finish of the end products—the result of printing and drying process variances—and the particular stock of paper handled by each.

Pros & Cons of Sheet-Fed & Web Press Printing

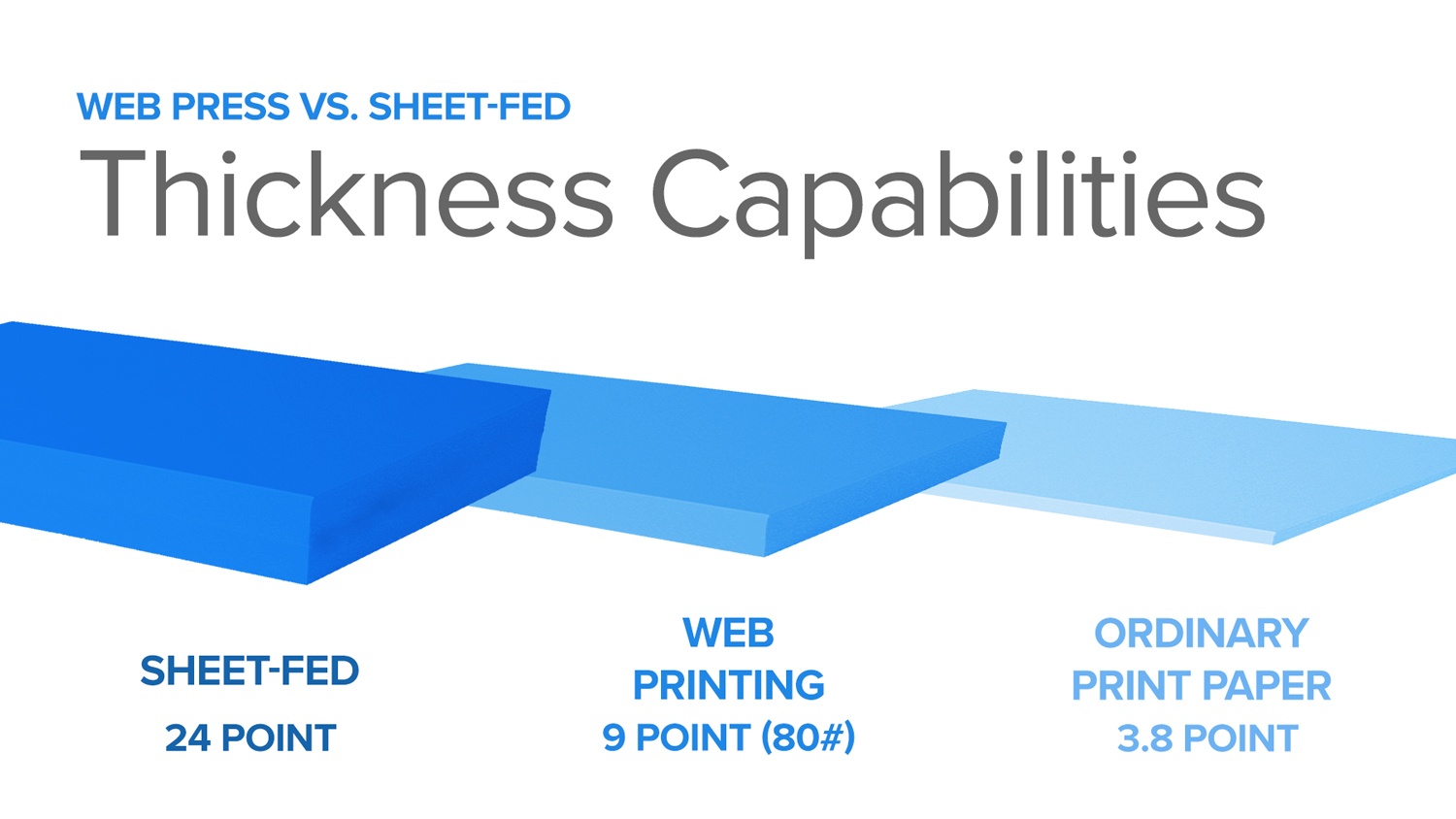

Both methods have advantages and drawbacks that make them ideal for particular orders based on their specific details. Sheet-fed printing can use a much more diverse array of stocks, including thicker options (typically up to 24-point). Web press printing is usually limited to a 9-point or 80# coated cover.

Finish options may also be limited, depending on the web press. Some can't print on a gloss-coated stock. The inking and drying approach—typically coldset or heatset—also has limitations, thereby reducing the options for specialty coatings and varnishes.

Sheet-fed printers can print larger formats on heavier stock and/or specialty paper, making this method perfect for brochures, order cards, postcards, complex lithographed envelopes, basic bi-colored letterheads, and other projects that require more flexible options. Web printing is best for newspapers, catalogs, and high-quality, glossy magazines. Its flexible format and speed make it ideal for long-run orders.

The finish impacts how recipients view the featured clients and merchandise, so it's important to choose wisely.

Design Distributors: Industry Experts in Sheet-Fed & Web Press Printing

As your one-stop direct mail partner, we offer sheet-fed and web press printing options, digital printing services, and much more—enabling us to create and execute your promotional campaign, no matter its unique needs. We hold ourselves accountable for getting your printing done right the first time, on time, every single time. Contact us today.

[Originally published: October 24, 2018]

If you need more information on the differences between sheet-fed and web press printing,

If you need more information on the differences between sheet-fed and web press printing,